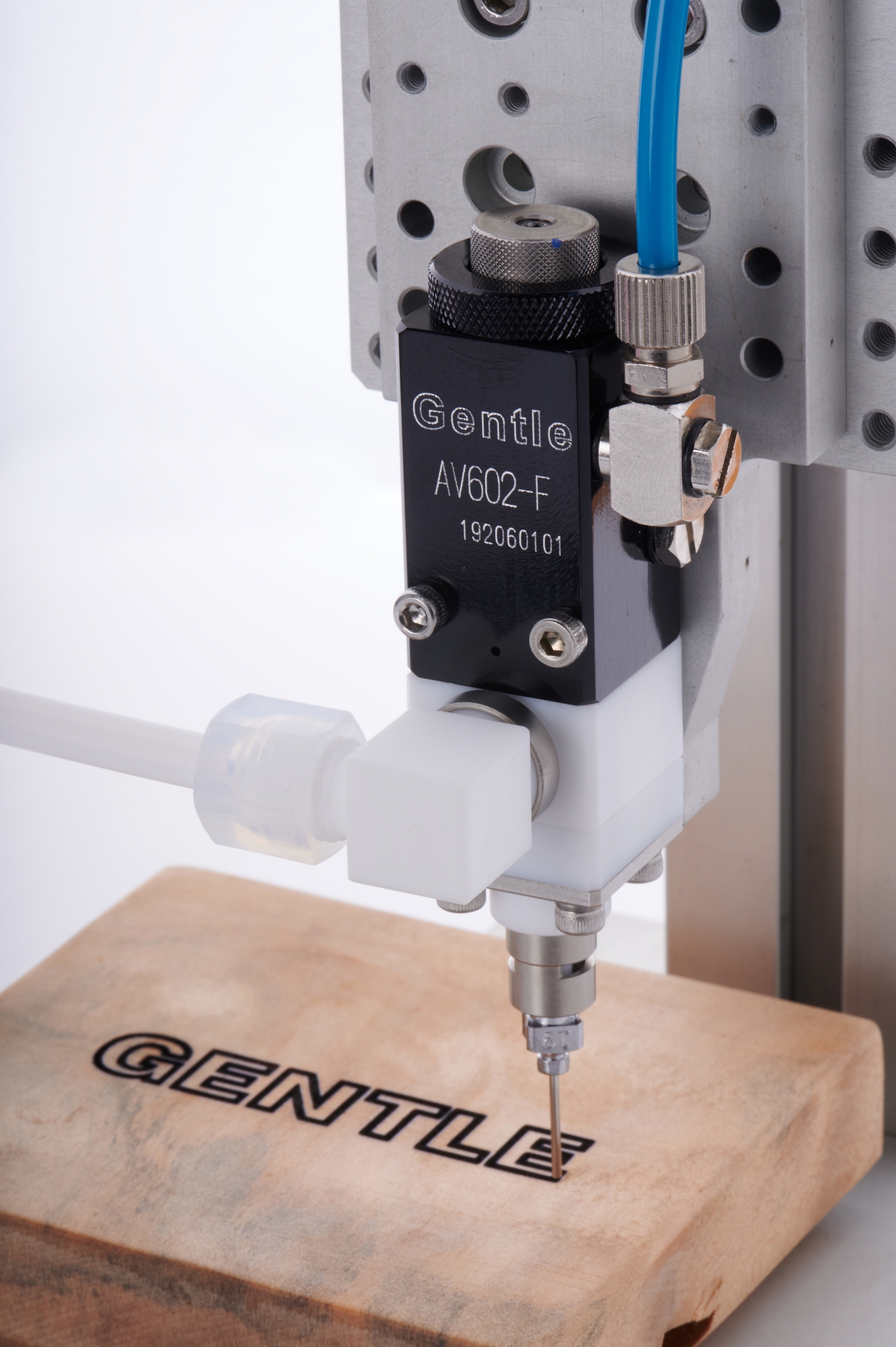

Are you familiar with how to properly use a dispensing machine? Dispensing technology has become indispensable in industries across the globe. Whether you're new to dispensing or looking to refine your skills, this 6-step guide will walk you through the proper use, sequence, and key precautions for optimal performance. Get the best results by pairing the right adhesive material, dispensing machine, and needle, ensuring everything is applied precisely to the right spots. From medical devices to aerospace, dispensing is enhancing efficiency and precision across multiple sectors.

Table of Contents

Correct Usage & Sequence for Dispensing

Dispensing is a crucial process in manufacturing and assembly. In simple terms, it's the method of precisely applying adhesives, sealants, or other liquid materials to specific areas for bonding, sealing, protection, or assembly. When done right, dispensing guarantees stable, reliable product quality and can even extend the life of your products.

Follow these steps to ensure flawless dispensing:

1. Prepare the Work Environment

Precision is key. Ensure your workspace is clean, with optimal temperature and humidity levels, so that the adhesive material flows and cures correctly without interference.

2. Choose the Right Adhesive & Dispensing Equipment

Select the adhesive based on the product's specifications and chemical properties. Choose the appropriate dispensing equipment (pneumatic, peristaltic, non-contact, heated systems) and select the correct needle based on the adhesive's viscosity and other characteristics.

3. Adjust the Dispensing Equipment

Before dispensing, plan your dispensing path and adjust the pressure and speed of the machine. This ensures uniform flow and precise control over the amount of material dispensed.

4. Verify Component Position for Accuracy

Double-check the positioning of your components, as well as the dispensing parameters, to ensure everything aligns perfectly for precise application.

5. Start Dispensing

Activate the dispensing machine and monitor the material flow and coverage. Regularly check and adjust the dispensing parameters, speed, and material volume to ensure consistent results.

6. Cleaning and Maintenance

After dispensing, immediately clean your equipment to prevent material from solidifying and clogging the needle. Regular maintenance keeps your equipment running smoothly, ensuring long-term performance. If you're not using the machine for an extended period, it's a good idea to disconnect the power.

What to Do with Residual Adhesive? Cleansing Tips

If leftover adhesive hardens inside the machine or needle, it can affect the flow and interfere with the dispensing process. Here's how to handle residual adhesive:

1. Prepare Solvents & Cleaning Tools

Choose the appropriate solvent based on the adhesive. Common solvents include acetone, alcohol, or dedicated adhesive removers. Use soft, lint-free cloths or cotton swabs to clean the surface. Be sure to wear protective gloves, goggles, and a mask when handling solvents.

2. Ensure a Safe Cleaning Area

Make sure the cleaning area is well-ventilated. Place the components you're cleaning on a stable surface to avoid accidents during the process.

3. Apply Solvent to Dissolve Residual Adhesive

Gently apply the solvent to the residue and let it sit for a few minutes to soften and dissolve the adhesive.

4. Clean the Residual Adhesive

Use lint-free wipes or cotton swabs to gently wipe away the softened adhesive. Repeat the process if necessary until the residue is completely gone.

5. Final Surface Check

After cleaning, inspect the surface to ensure no adhesive remains. Wipe down with alcohol or acetone to remove any leftover solvent.

6. Clean the Tools

Once the cleaning process is complete, make sure to wash all cleaning tools to prevent any leftover solvents or adhesives from affecting future use.

4 Key Dispensing Considerations

Now that you know how to use and clean your dispensing equipment, here are additional tips to ensure smooth operation:

- Choose the Right Dispensing Equipment: For optimal coating, selecting the right dispensing robot, machine, and needle is essential. Consult professionals to ensure the equipment suits your needs and maintains consistent results.

- Selecting the Right Adhesive: Choose the right adhesive based on your specific application. Make sure it's compatible with the materials you're working with. Seek professional advice when necessary to ensure a perfect match.

- Ensure a Safe Working Environment: Always maintain a clean, safe working space to prevent accidents. Ensure that operators are equipped with the proper safety gear and the workspace is tidy and well-organized.

- Proper Use of Tools: Before starting, always test and adjust your equipment. After use, perform a thorough cleaning and maintenance routine to keep everything in optimal working condition.

Common Dispensing FAQs

Have questions or concerns about selecting or operating dispensing equipment? Here are answers to some frequently asked questions:

Q1: Manual vs. Automatic — Which Should I Choose?

A: It depends on your production needs, budget, and product characteristics. For high-volume or repetitive tasks, automatic dispensing is ideal. For smaller runs or more intricate work, manual dispensing provides greater flexibility.

Q2: How Do I Determine the Right Size and Specifications for Dispensing Equipment?

A: The size and specs of your dispensing equipment depend on the dimensions, shape, and surface characteristics of the components, as well as the adhesive's viscosity. Consult with suppliers to choose the right equipment.

Q3: Do Dispensing Equipment Operators Need Training?

A: Yes, operators must undergo training to ensure safe and correct dispensing. Training should cover equipment operation, adhesive chemistry, safety, maintenance, and troubleshooting.

Q4: How Do I Test and Ensure the Quality of Dispensing Work?

A: Quality can be assessed through visual inspections, physical measurements, and tests like volume checks, hardness, and resistance tests. Develop appropriate testing standards based on production requirements.

Q5: How Often Should Dispensing Equipment Be Maintained?

A: Maintenance frequency depends on usage, environment, and adhesive characteristics. Perform regular cleaning after each use and check equipment periodically. Always replace consumables like needles and seals to maintain quality.

Conclusion: Ensuring Optimal Dispensing with the Right Equipment

The success of dispensing operations depends heavily on the selection and proper use of equipment. Partner with experienced suppliers who provide comprehensive product information and ensure you choose the right dispensing systems. GENTLE's high-quality dispensing products, made in Taiwan, offer cost-effective solutions while reducing production costs. With over 30 years of experience, GENTLE offers professional consultations to help you select the best solutions for your dispensing needs.

Further Reading:

What is a Dispensing Machine? Easy Operation & Principles Explained!

What is Dispensing Technology? Why It's Essential in Modern Manufacturing