- All Products

- Pneumatic Series

- GENTLE Pneumatic Fittings

- GENTLE Ionizer

- CONVUM Ltd.

- FUJIKURA

- FUJI LATEX Co., Ltd.

- KOGANEI Corporation

- iB series

- Air Cylinders, Hands

- Air Valves

- Air Filters, Regulators, Pressure Gauges

- Flow Rate Sensor Switches, Plachain Ducts, Pressure Switches

- Vacuum Equipment, Pads

- Electric Actuator

- Environmental Hygiene Equipment

- Static Electricity Removal

- Fluororesin Products

- Fixed Discharge Pump

- Medium Control Equipment

- Pulse Blow Series

- NKE Corporation

- TAKEX

- Dispensing Series

- Dual-Pass Inline Design: Simplifies piping with direct tube-to-tube connection, eliminating extra fittings.

- Stable Low-Flow Control: Optimized bore ensures smooth, precise regulation even at micro flows.

- Quick Installation: Dual one-touch inlets provide airtight connections and easy disassembly.

- Durable Build: Nickel-plated brass and engineered plastics ensure long service life without deformation.

- Dual-Color Options: Available in black and gray-white (-GW) for flexible integration with equipment.

- Applications: Perfect for linear slides, modular automation equipment, and systems requiring straight inline piping with stable speed control.

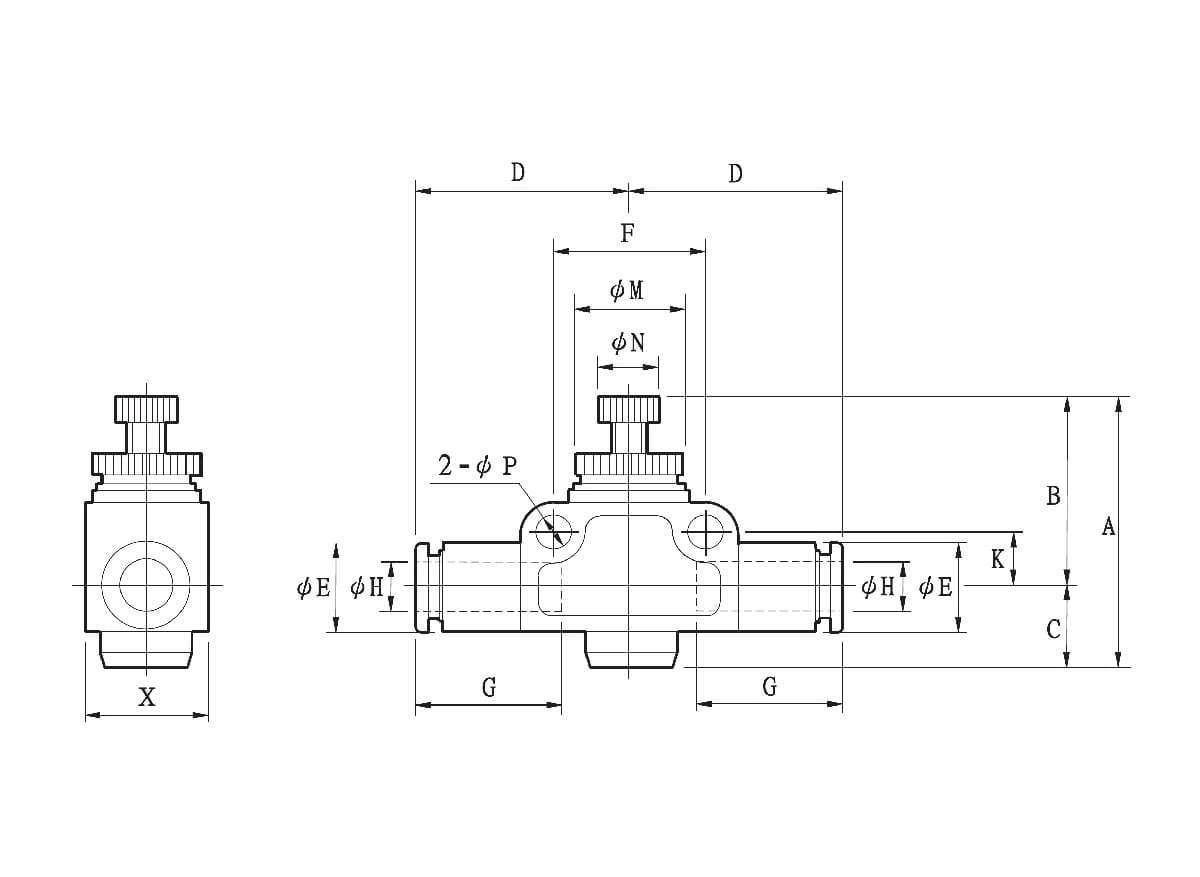

Metric Dimension

| Model | H Tube Size | A | B | C | D | E | F | G | K | M | N | P | X | Weight (g) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Max | Min | |||||||||||||

| SSU4 | 4 | 28.8 | 26 | 22.3 | 19.5 | 6.5 | 20.7 | 10.5 | 14 | 14.9 | 6.5 | 8 | 5 | 3.2 | 11 | 12.4 |

| SSU6 | 6 | 41.6 | 36 | 30.6 | 25 | 11 | 25.1 | 13 | 20 | 17 | 8.5 | 13 | 8 | 4.3 | 15 | 28.5 |

| SSU8 | 8 | 47.4 | 42.9 | 35.4 | 30.9 | 12 | 27.6 | 15 | 22 | 18.1 | 9.5 | 13 | 10 | 4.3 | 18 | 43.1 |

| SSU10 | 10 | 52.4 | 45.7 | 40.4 | 33.7 | 12 | 32 | 18 | 26 | 20.2 | 11.0 | 16 | 13 | 4.3 | 21 | 68.7 |

| SSU12 | 12 | 56.3 | 49.2 | 40.3 | 33.2 | 16 | 37.4 | 21 | 32 | 23.3 | 13.0 | 19 | 13 | 4.3 | 28 | 115 |

Q1: What's the advantage of union straight design?

A: It connects tubing directly, reducing bends and extra fittings for a simplified layout.

Q2: Where is the SSU series best applied?

A: Commonly used in linear slides, automation modules, and straight-line piping systems.

Q3: How does it perform in low flow ranges?

A: It maintains precise, stable control at minimal flow, reducing cylinder vibration and overshoot for smooth, accurate operation.

Q4: What should be noted during installation?

A: Ensure tubing ends are cut square and inserted fully until they bottom out in the inlets, guaranteeing airtight performance and preventing leakage.

Q5: How does it compare to typical inline valves?

A: While standard models focus only on basic specs, the GENTLE SSU series offers full tube sizes (4–12 mm), robust structure, and dual-color options, ensuring durability and precise control.