Pneumatic Fitting Specifications and Types: How to Choose the Right One & Discover Its Benefits!

In today's industrial and automation environments, pneumatic fittings play a crucial role in pneumatic systems. But do you understand the specifications and types of pneumatic fittings? And how do you properly select the right fitting? This article outlines the specifications, performance, and safety considerations for pneumatic fittings, providing practical guidance to help you choose the right fitting for your needs, advancing your business to the next level.

Table of Contents

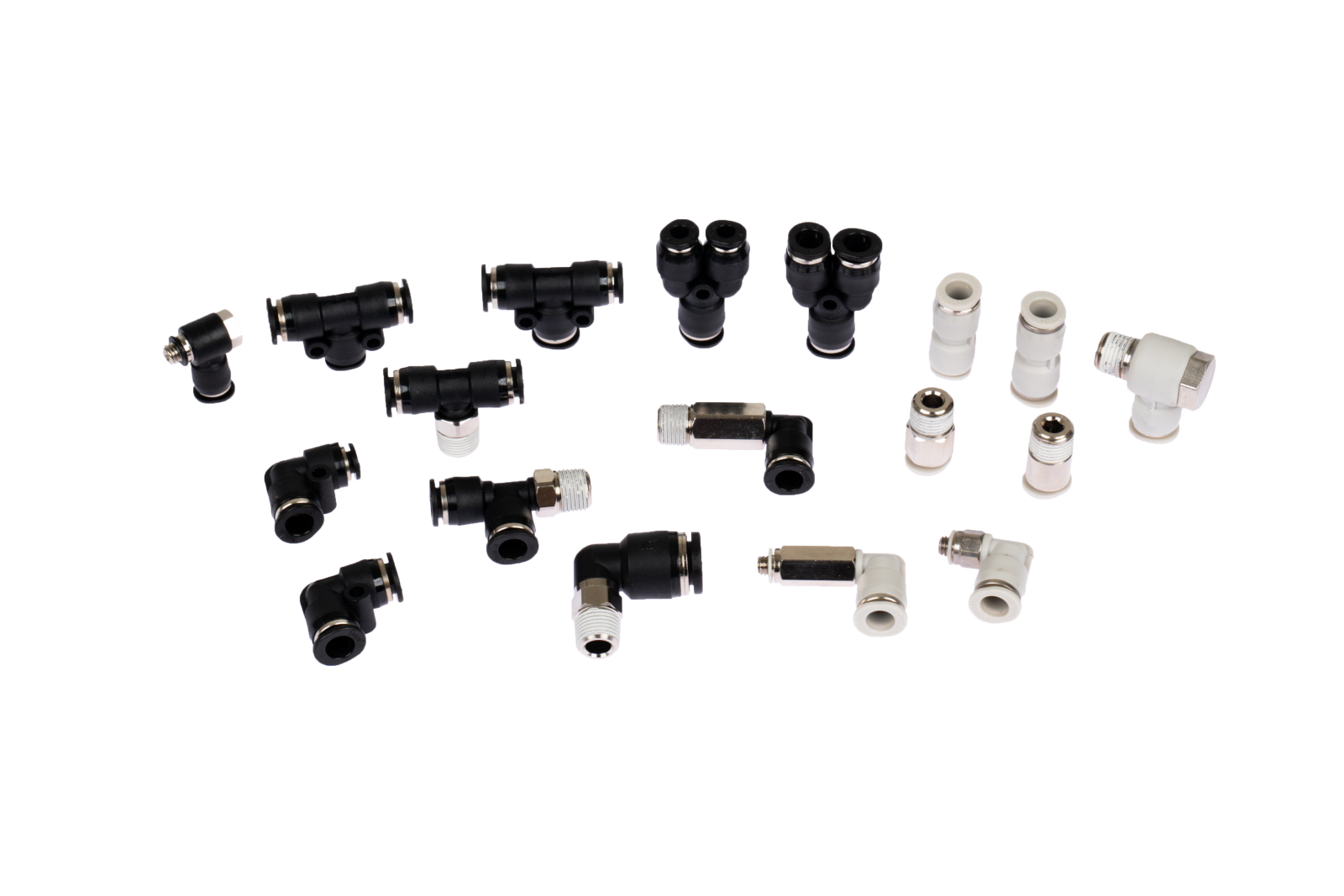

Pneumatic Fitting Specifications & Types

We will begin by breaking down pneumatic fittings into three categories: appearance style, material, and connection type.

1. Appearance Style:

| No. | Style | Features |

| 1 | Elbow Fittings | Angled fittings, typically 90 degrees, used to connect pneumatic hoses. Compact and versatile, suitable for PU and nylon tubing. |

| 2 | Straight Fittings | Fittings with one threaded side and a pneumatic hose clamp, used as adapters. Highly secure and compatible with a wide range of instruments. |

| 3 | T Fittings | Push-in design, securely connects to threaded ports. Ideal for vacuum or positive pressure applications, with low leakage rate. |

| 4 | Y Fittings | Suitable for a variety of applications, offers quick connect and disconnect, full flow, vacuum resistance, and can be operated with one hand. |

| 5 | Functional Fittings | Versatile fittings used for different functions such as blocking, venting, flow control, air supply, and silencing. |

2. Material:

| No. | Material | Advantages | Disadvantages |

| 1 | Aluminum Alloy | Lightweight, corrosion-resistant | Lower tensile strength |

| 2 | Brass | Corrosion-resistant, durable, excellent conductivity and high-temperature ductility | Lower tensile strength |

| 3 | Stainless Steel | Corrosion-resistant, chemically resistant, high strength | Lower tensile strength |

| 4 | Plastic | Lightweight, cost-effective, weather and UV resistant | Lower tensile strength |

| 5 | Composite Materials | Chemically resistant, temperature-resistant, high strength | Lower tensile strength |

3. Connection Type:

| No. | Type | Applicable Range | Temperature Range |

| 1 | Push-In Pneumatic Fittings | Low to medium-pressure systems, typically used in industrial and light applications | Low to medium temperatures |

| 2 | Tube-to-Tube Pneumatic Fittings | Medium to high-pressure systems, used for air compression and liquid transport | Low to high temperatures |

| 3 | Nut-Type Pneumatic Fittings | Low to high-pressure systems, widely used in industrial and automotive applications | Low to high temperatures |

| 4 | Nut-Type Hook Pneumatic Fittings | Low to medium-pressure systems, common in pneumatic systems and tools | Low to medium temperatures |

Key Considerations for Selecting Pneumatic Fittings - Q&A

Q1:Why is the work environment important?

A:The work environment directly impacts the performance of pneumatic systems. Factors such as temperature, humidity, and chemical exposure must be considered to ensure the selected fitting operates reliably and maintains system stability and longevity.

Q2:WHy is it important to determine the required air pressure or PSI specifications?

A:Pneumatic fittings are often rated for specific pressure ranges. Operating within these ranges ensures optimal performance. Exceeding these pressures may lead to system failure, leaks, or damage.

Q3:Why should I check the usage specifications?

A:Different industries have their own safety standards for pneumatic fittings. For example, in food processing, air purity and microbial control requirements are very strict, and oil-based lubricants are prohibited.

Q4:Why is the fitting material so important?

A:The material affects the durability and adaptability of pneumatic fittings. Select the right material—such as brass, stainless steel, or plastic—based on the work environment and fluid properties to ensure long-term reliability.

Q5:What should I consider regarding tube and thread types?

A:Properly matching the tube type and size, as well as understanding the required thread type and size, ensures seamless connections, minimizing the risk of leaks and system failure, while ensuring the overall performance of the pneumatic system.

Recommended GENTLE Series Pneumatic Fittings

GENTLE offers a range of pneumatic fittings in both standard and mini sizes to meet diverse application needs.

Advantages of the GENTLE Series:

- Quick- connect and disconnect mechanism, easy to operate manually without the need for tools or adhesives, and reusable.

- A wide variety of styles, sizes, and thread combinations to choose from.

- Frequent tube replacements are easier and more cost-effective due to the quick-connect and disconnect design.

- Metal bodies are nickel-plated brass, and plastic bodies are engineered plastics with durable, leak-proof rubber gaskets for superior longevity compared to other brands.

- Compatible with both nylon and PU tubes.

- Standardized thread sealant for all fittings.

Top 3 Best-Selling GENTLE Series Pneumatic Fittings

| Model | Features |

| L Type Speed Controller

|

|

| Straight Type Quick Fitting

|

|

| T Type Quick Fitting

|

|

By now, you should have a clearer understanding of pneumatic fitting specifications, types, and the essential factors to consider when selecting the right one. Choosing the correct materials, models, and connection types will enhance system efficiency and safety, ensuring the longevity and stability of your pneumatic system. Follow the guidelines provided to confidently select the most suitable GENTLE series pneumatic fittings, delivering optimal performance for your applications.

Further Reading:

What's a Pneumatic Quick-Connect Fitting? A Comprehensive Guide to Materials & Installation Methods!

What's a Pneumatic Fitting? A Quick 3-Minute Guide on Specs, Types, and Applications