- All Products

- Pneumatic Series

- GENTLE Pneumatic Fittings

- GENTLE Ionizer

- CONVUM Ltd.

- FUJIKURA

- FUJI LATEX Co., Ltd.

- KOGANEI Corporation

- iB series

- Air Cylinders, Hands

- Air Valves

- Air Filters, Regulators, Pressure Gauges

- Flow Rate Sensor Switches, Plachain Ducts, Pressure Switches

- Vacuum Equipment, Pads

- Electric Actuator

- Environmental Hygiene Equipment

- Static Electricity Removal

- Fluororesin Products

- Fixed Discharge Pump

- Medium Control Equipment

- Pulse Blow Series

- NKE Corporation

- TAKEX

- Dispensing Series

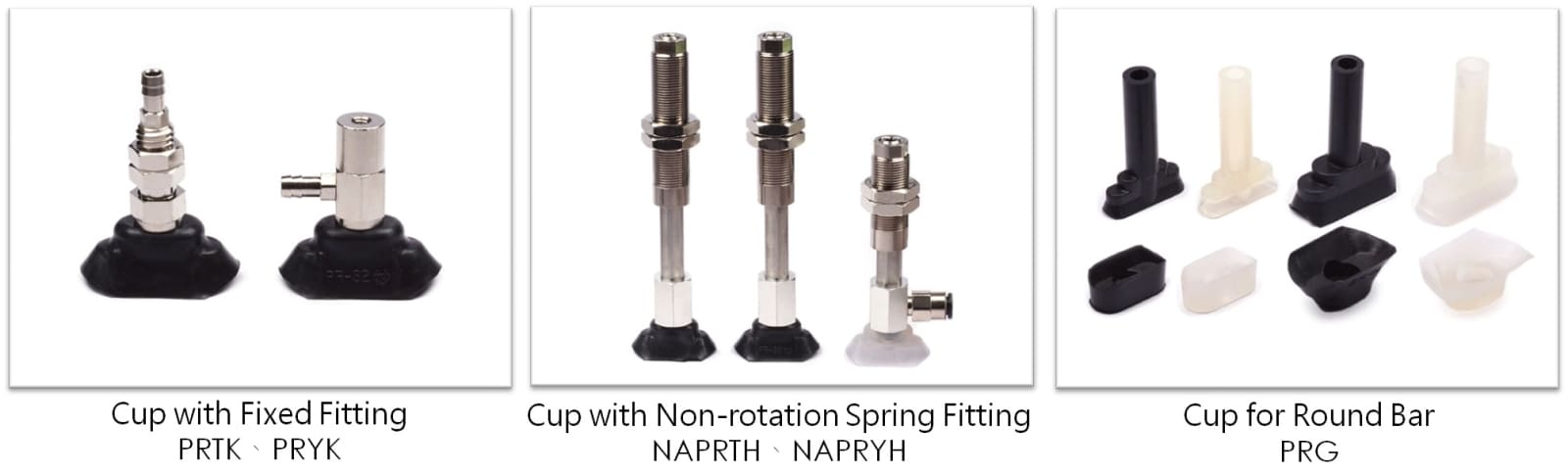

- Profiled for Cylindrical Parts: Contact geometry tailored to rods/tubes for higher conformity and stable grip with reduced lateral slip.

- Best on Smooth Round Surfaces: Designed for external pickup of cylindrical and tubular workpieces.

- Size Range (model sizes): ø9.5×25, 12.5×23, 15×30, 32×32 mm.

- Material Options (Code | Material | Key traits):

- N | NBR: general-purpose, oil resistant.

- S | Silicone: soft, conformable, low marking for appearance-sensitive parts.

- Easy Integration: Compatible with common pad holders and vacuum fittings.

- Applications: Tube loading/sorting, rod part positioning, post-cut tube pick, and general FA handling of cylindrical parts.

Q1: What are PR pads mainly used for?

A: Handling tubes, rods, and other cylindrical parts on automation and assembly lines.

Q2: Do they work on rough or textured pipes?

A: They perform best on smooth surfaces. For rough/porous profiles, consider PD (foam) or PL (multi-bellows) pads for better conformity and sealing.

Q3: What sizes are available?

A: ø9.5×25, 12.5×23, 15×30, 32×32 mm. Size by tube diameter, contact length, and payload.

Q4: Are they suitable for high-speed automation?

A: Yes. Use appropriate vacuum generators/orifices and refine accel/decel profiles to limit lateral forces.

Q5: How should I choose between N and S materials?

A: N (NBR) is oil-resistant and versatile; S (Silicone) offers higher conformity and lower marking—ideal for appearance-critical parts.