What Are Pneumatic Fittings? A 3-Minute Guide to Types, Specifications, and Key Considerations

Pneumatic fittings play a vital role in modern pneumatic systems, offering convenient connections that improve operational efficiency. In this article, we'll explore the different types, materials, and applications of pneumatic fittings, helping you make an informed choice when selecting the right components for your system.

Table of Contents

What Are Pneumatic Fittings?

Pneumatic fittings, also known as quick-connect fittings, are essential components in automation systems. They are used to connect pneumatic systems' pipelines, components such as valves, cylinders, and hoses, ensuring that air is efficiently transported without leaks or pressure drops during the process.

Types of Pneumatic Fittings

Pneumatic fittings come in various types, each designed for different applications. Here's an overview of the most common types:

- Plastic Pneumatic Fittings: Corrosion-resistant and ideal for low-pressure environments. These are commonly used for general applications.

- Aluminum Pneumatic Fittings: Durable, corrosion-resistant, and suitable for moderate pressure environments.

- Stainless Steel Pneumatic Fittings: Known for high temperature and corrosion resistance, these fittings are perfect for high-pressure and industrial settings.

- Brass Pneumatic Fittings: Excellent for heat conduction and corrosion resistance but heavier than other materials.

- Rubber Pneuamatic Fittings: Designed for sealing and vibration damping, these are often used as complementary components.

Pneumatic fittings can also be categorized based on their connection design:

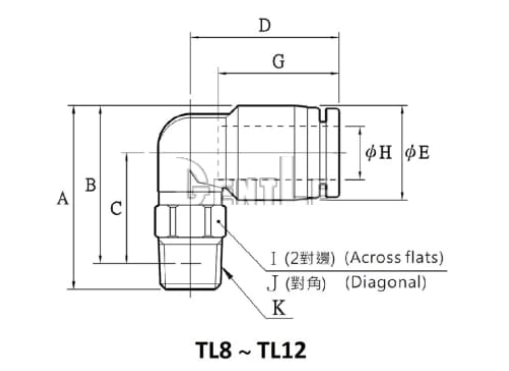

- Elbow Fittings: Designed with a 90-degree angle for connecting hoses using push-in or insert connections.

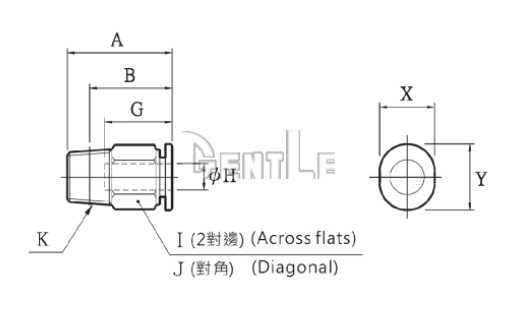

- Straight Fittings: These allow two hoses to connect in a straight line, supporting various pipe diameters.

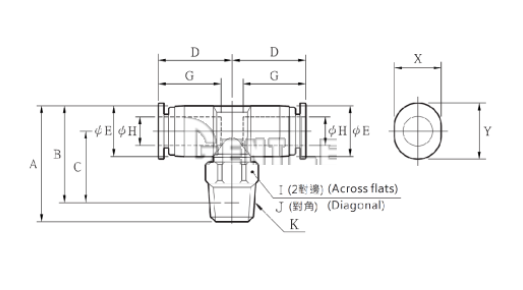

- T-Fittings: A push-in design that enables branching with multiple configurations, allowing for pressure increase or reduction.

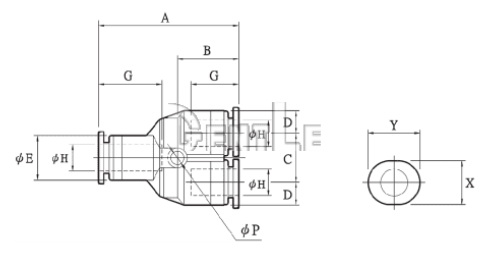

- Y-Fittings: These fittings support quick connection and disconnection, often designed for single-handed operation.

- Functional Fittings: Versatile fittings that support multiple connections, ideal for various applications.

Based on customer requirements, various fitting combinations and recommendations are provided. GENTLE primarily offers plastic quick-connect fittings, with a special emphasis on our mini fittings. These mini fittings offer the same functionality, material properties, and performance as standard fittings but are designed to be more flexible, allowing for easier installation in tight spaces without sacrificing performance.

Common Pneumatic Fitting Specifications

1. Elbow Type Mini Pneumatic Fittings (L-Shaped)

- View detailed specifications: Elbow Type Mini Quick Fitting (L Type)

- Metric dimension

|

| Tube Size 4 | Tube Size 6 | Tube Size 8 | Tube Size 10 | Tube Size 12 |

| Model | TL4-M3M TL4-M5M TL4-M6M TL4-01M | TL6-M5M TL6-M6M TL6-01M | TL8-01M TL8-02M TL8-03M TL8-04M | TL10-01M TL10-02M TL10-03M TL10-04M | TL12-01M TL12-02M TL12-03M TL12-04M |

2. Straight Mini Pneumatic Fittings

- View detailed specifications: Straight Type Mini Quick Fitting

- Metric dimension

|

| Tube Size 4 | Tube Size 6 |

| Model | TS4-M3M TS4-M5M TS4-01M | TS6-M5M TS6-M6M TS6-01M |

3. T-Shaped Mini Pneumatic Fittings

- View detailed specifications: T Type Mini Quick Fitting

- Metric dimension

|

| Tube Size 4 | Tube Size 6 |

| Model | TT4-M3M TT4-M5M TT4-M6M TT4-01M | TT6-M5M TT6-M6M TT6-01M |

4. Y-Shaped Mini Pneumatic Fittings

- View detailed specifications: Union Y Type Mini Quick Fitting

- Metric dimension

|

| Tube Size 4 | Tube Size 6 |

| Model | UY4M | UY6M |

4 Key Considerations When Using Pneumatic Fittings

The installation and disconnection of pneumatic fittings are simple and tool-free, making them efficient and cost-effective for factory operations. However, to ensure optimal performance and safety, it's essential to follow these key considerations:

- Correct Pressure Range: Ensure the operating pressure falls within the fitting's rated range to prevent damage.

- Proper Installation: Follow the manufacturer's guidelines to prevent leaks or disconnections. Regularly inspects seals and connections.

- Material Compatibility: Select the appropriate material based on the type of fluid and operating conditions.

- Regular Maintenance: Keep fittings clean to prevent dirt buildup, which could affect performance. Regularly check for wear and replace parts as needed.

Pneumatic fittings are integral to enhancing work efficiency and maintaining the stability of pneumatic systems. Choosing the right fittings improves safety and prolongs equipment life. We hope this guide helps you better understand pneumatic fittings and select the best solutions for your pneumatic systems.

Further Reading:

What is a Dispensing Machine? Easy Operation & Principles Explained!

Pneumatic Fitting Specifications and Types: How to Choose the Right One & Discover Its Benefits!